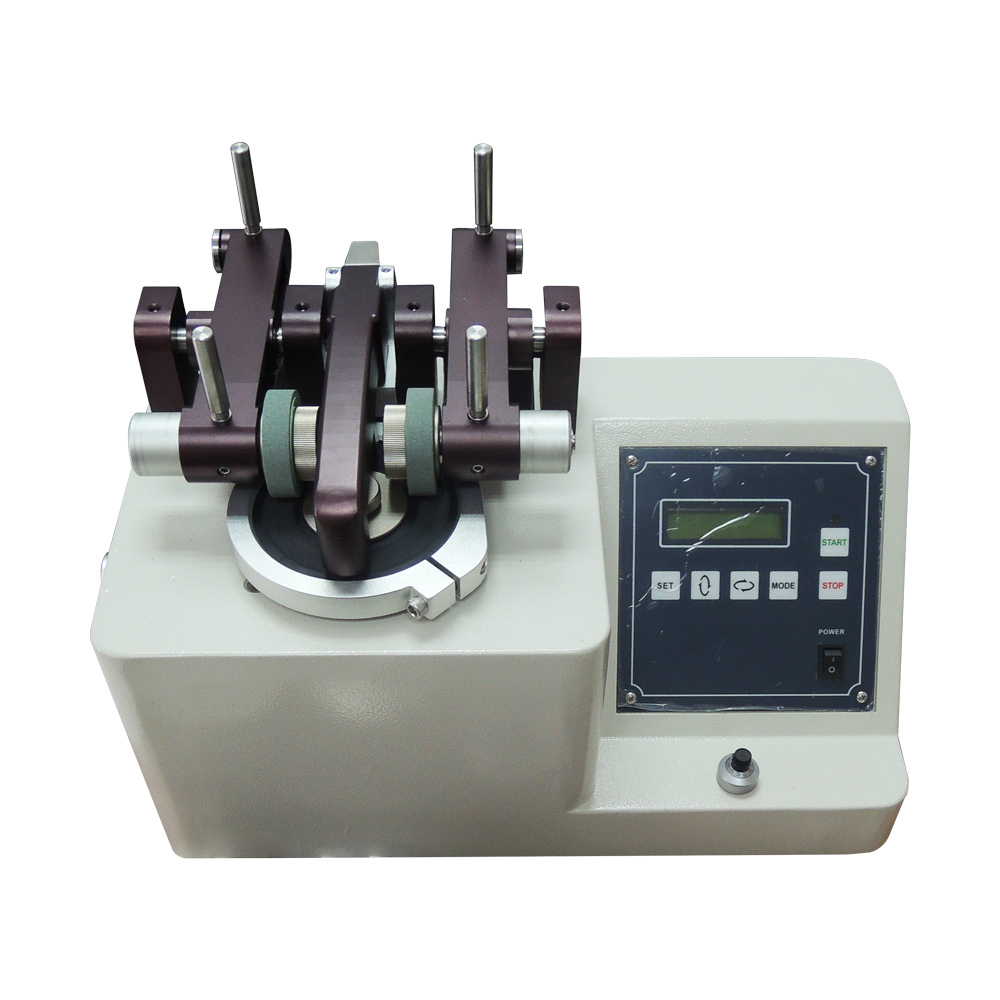

SL-L02 Astmd Taber Abrasion Tester

Standards of Astmd Taber Abrasion Tester:

ASTMD3884, ASTMD1175, ASTMD1044, ASTMD4060, TAPPIT476, ISO9352, ISO54701, JISK7204, JISA1453, JISK6902, JISL1096, JISK6964, DIN52347, DIN53109, DIN53754, DIN53799, etc.

Technical Parameters of Astmd Taber Abrasion Tester:

|

Specimen: |

120 × 6.5 × 3mm |

|

Load: |

250g, 500g, 1000g |

|

Counter: |

6 digit electronic display, automatic shut down |

|

Testing Disk Speed: |

0-70 Adjustable |

|

Machine Dimensions: |

30 × 43 × 30cm |

|

Machine Weight: |

30kg |

|

Attachment: |

A wrench, a group of grinding wheel, Fama (250g, 500g, 750g) each 2 PCS. Vacuum cleaner 1. |

|

Power Supply: |

AC220V/50Hz |

|

Abrasion Wheel Diameter: |

52.4mm |

|

Weights: |

250g, 750g, 1000g |

|

Gyration Speed: |

60 ~ 72+/-2rpm |

|

Counter: |

LCD display 0-999999 |

Use of Taber Abrasion Tester:

The abrasion resistance of the material is measured and the abrasion resistance of the product is evaluated by the abrasion test such as measuring the mass loss, thickness loss and light transmittance.

Applications of Taber Abrasion Tester:

Products used for testing plane such as: suitcase, carpet, cardboard, clothing, glass, plastic coating, ceramic tile, metal coating, paint, varnish, decorative sheet, high-pressure sheet, plastic, textile, elastic floor mat, traffic paint, anodized layer, blanket, electronic components, decorative plate, wax, label, leather cover, dental materials, automobile interior decoration, resin, furniture, etc.

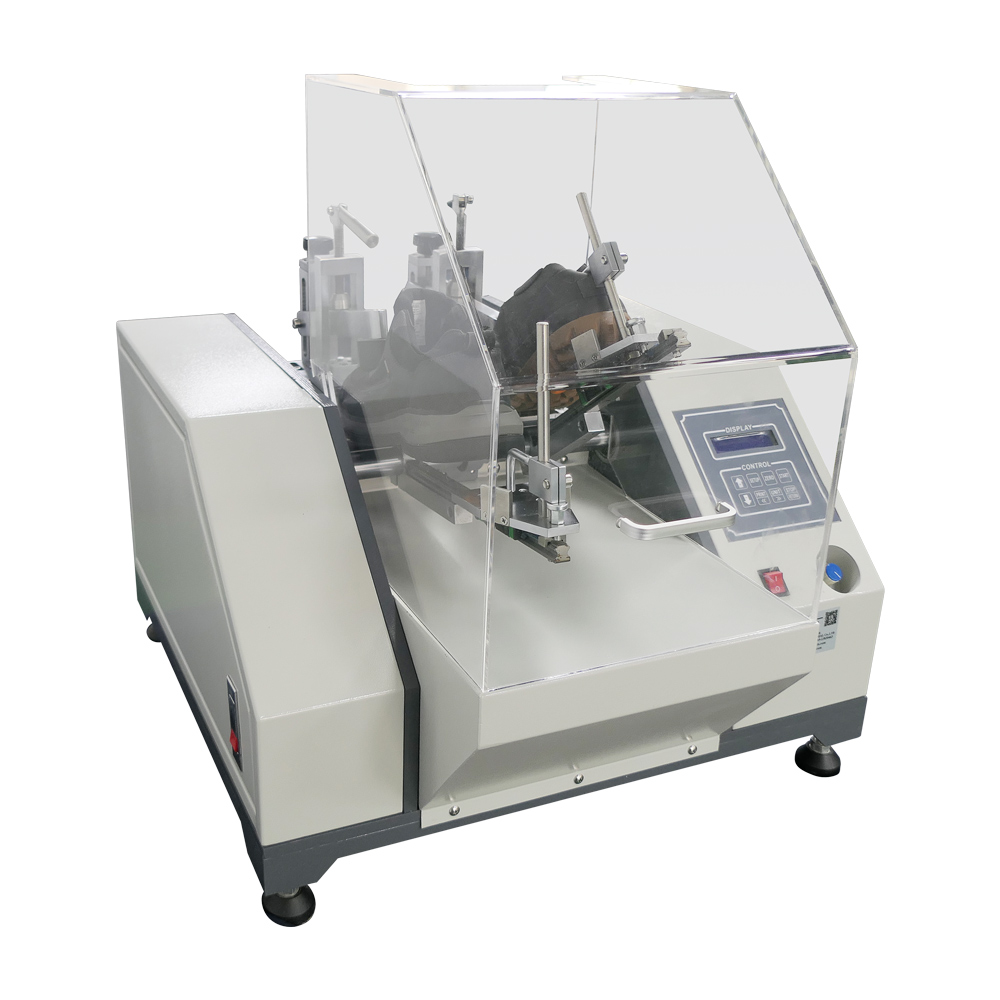

Applications Principle of Taber Abrasion Tester:

Put the material to be tested on the rotary table and the two grinding wheels press the material with a certain weight to make it wear. When the sample with an area of 10x10cm is subjected to abrasion. The surface material of the sample is abraded by all angle particles or silk fabrics to form a complete ring. The grinding wheel rotates with the rotating surface of the sample disk, resulting in relative movement and wear. During the rotation, the offset of the grinding wheel shaft relative to the rotating shaft of the rotary table generates sliding movement, thus wearing the material.

- [email protected]

- skylineinstruments

- +86 13751491529

- +86 13751491529

+86 13751491529

+86 13751491529 +86 13751491529

+86 13751491529