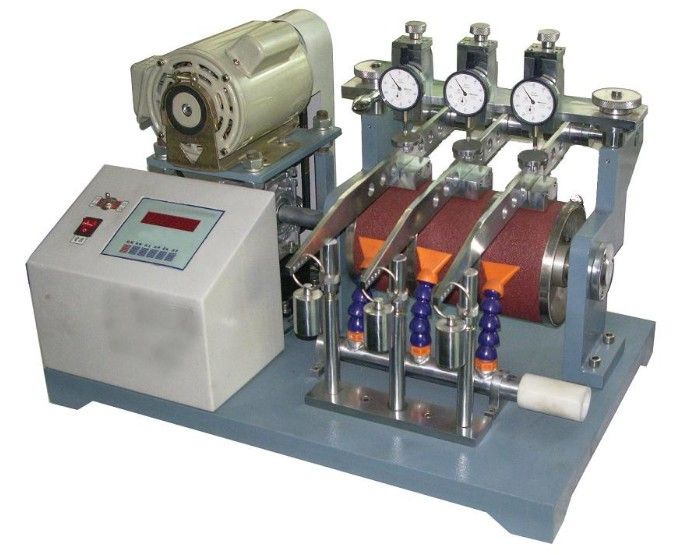

SL-L63 De mattia Zigzag Testing Machine

Standards of De mattia Zigzag Testing Machine:

ASTM D430, ASTM D813, GB/T 13935

Technical Parameters of De mattia Zigzag Testing Machine:

|

Temperature range: |

room temperature + 10℃ ~ 150℃ |

|

Speed: |

5 Hz |

| Clamp: |

10 groups, each group can clamp 2 pieces (20 pieces in total) |

| Time setting: |

0 ~ 999 hours |

| Test piece size: |

vulcanized rubber 150 (L) * 25 (W) * 6.35 (T) mm |

| Temperature control: |

adopt PID intelligent parameter automatic control and electronic LED display |

|

Circulation system: |

fan forced circulation system |

| Inner box material: |

SUS304 # stainless steel |

|

Size: |

125 (W) * 102 (d) * 180 (H) cm |

|

Power supply: |

AC220V / 380V 3PH 20A 3kw |

Features of De mattia Zigzag Testing Equipment:

The high-temperature demattia fatigue tester conforms to ASTM d430, ASTM d813 and GB / T 13935.

It has transparent windows, and can directly observe the experimental conditions by using multi-layer vacuum defogging transparent landscape windows.

Clip in the specimens of the machine,after continuous bending fatigue of cracking degree observation in solution or compare their durability.Suitable for material such as rubber,leather,synthetic leather,shoe sole.

What is the need for testing in shoe industry?

The resistance to flexural failure of rubber or plastic coated fabrics was tested by the De Mattia method.

Test principle:Fold the rectangle of coated fabric twice so that its side-length edges meet to form a 125*12.5 mm strip. The folded strip is mounted between a pair of flat grips, one of which is capable of reciprocating linear motion, causing the folded specimen to bend outward 5 times per second. This high-speed folding of the specimen continues until a predetermined number of cycles or until the specimen is visibly broken.

- [email protected]

- skylineinstruments

- +86 13751491529

- +86 13751491529

+86 13751491529

+86 13751491529 +86 13751491529

+86 13751491529