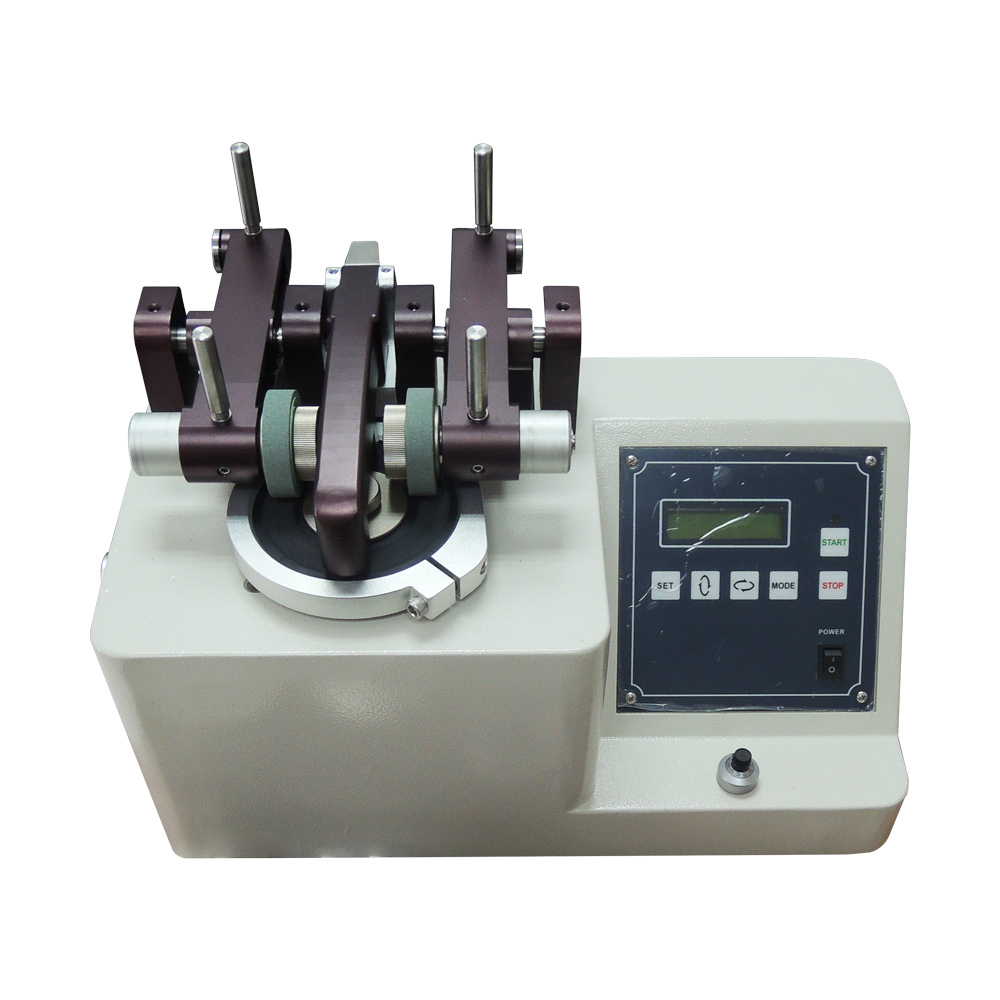

SL-L03 Din Abrasive Tester

Standard of Din Abrasive Tester:

GB/T20991-2007, DIN53516, IS04649, IS020871, ASTM D5963, IS0EN20344-2011

Technical Parameter of Din Abrasive Tester:

|

Roller Diameter: |

Ф 150mm |

|

Rubbing Length: |

40 ± 0.2m |

|

Distance Setting: |

20m / 40m preset |

|

Lateral DIsplacement of Clamp: |

4.20 ± 0.04r/min |

|

Roller Speed: |

40 ± 1R / min |

|

Test Mode: |

rotation / non rotation preset |

|

Load: |

2.5 ± 0.1N, 5 ± 0.1N, 10 ± 0.1N |

|

Sandpaper Granularity: |

60 # German original factory |

|

Dimension: |

95 * 66 * 31cm |

|

Weight: |

55kg |

|

Power: |

AC220V50HZ |

Features of Din Abrasive Tester:

This machine is applicable to the abrasion resistance test of polyester sole, finished sole and polymer sheet material.

When the abrasion wheel is rotating, the sample will be abraded by sandpaper with a certain degree of sand to produce abrasion amount, So as to evaluate its abrasion performance. It has high performance. Good reproducibility and easy operation.

Introduction of Din Abrasive Tester:

The main function of the DIN abrasive tester is to test the friction of the surface with specific sandpaper for a certain period of time, and then evaluate the condition, weight, volume and thickness of the material surface, from which the abrasive properties of the material are assessed.

Main Features of Din Abrasive Tester:

The tester is highly efficient, repeatable and easy to operate, and is suitable for testing the abrasive properties of materials such as elastic materials, rubber, tires, conveyor belts, conveyors, shoe soles, synthetic leather, leather, etc.

What is DIN abrasion test?

DIN abrasion tester is a combination of precision electronic balance, unique software for DIN abrasion, and density accessories. According to the DIN abrasion test method and the Archimedes buoyancy method, the physical property data such as the abrasion amount are obtained.

principle: During the wear process of two objects, the amount of surface material loss in relative motion is evaluated by the friction and wear test under specified conditions.

- [email protected]

- skylineinstruments

- +86 13751491529

- +86 13751491529

+86 13751491529

+86 13751491529 +86 13751491529

+86 13751491529